WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

Three years ago, Khan, a foreign customer, consulted on the Internet about the scrap motor rotor crusher. After shopping around, he chose TONGLI SHREDDER. After purchasing the air ticket, Khan and his colleagues visited the factory together. Tongli workers brought scraps of motor rotors to test the machine.

Waste motor rotors contain a large amount of important metal materials such as copper and iron. Relying on manual separation of copper and iron is not only inefficient, but also costly. Now the most expensive thing is labor. As a new type of scrap metal processing equipment, the motor rotor crusher can crush the recovered various rotors by machines, break up the various parts of the motor rotor, and separate the copper and iron, and then use the sorting equipment to separate the copper and iron. Separately, the speed is fast and the effect is good.

How to crush and recycle used motor rotors?

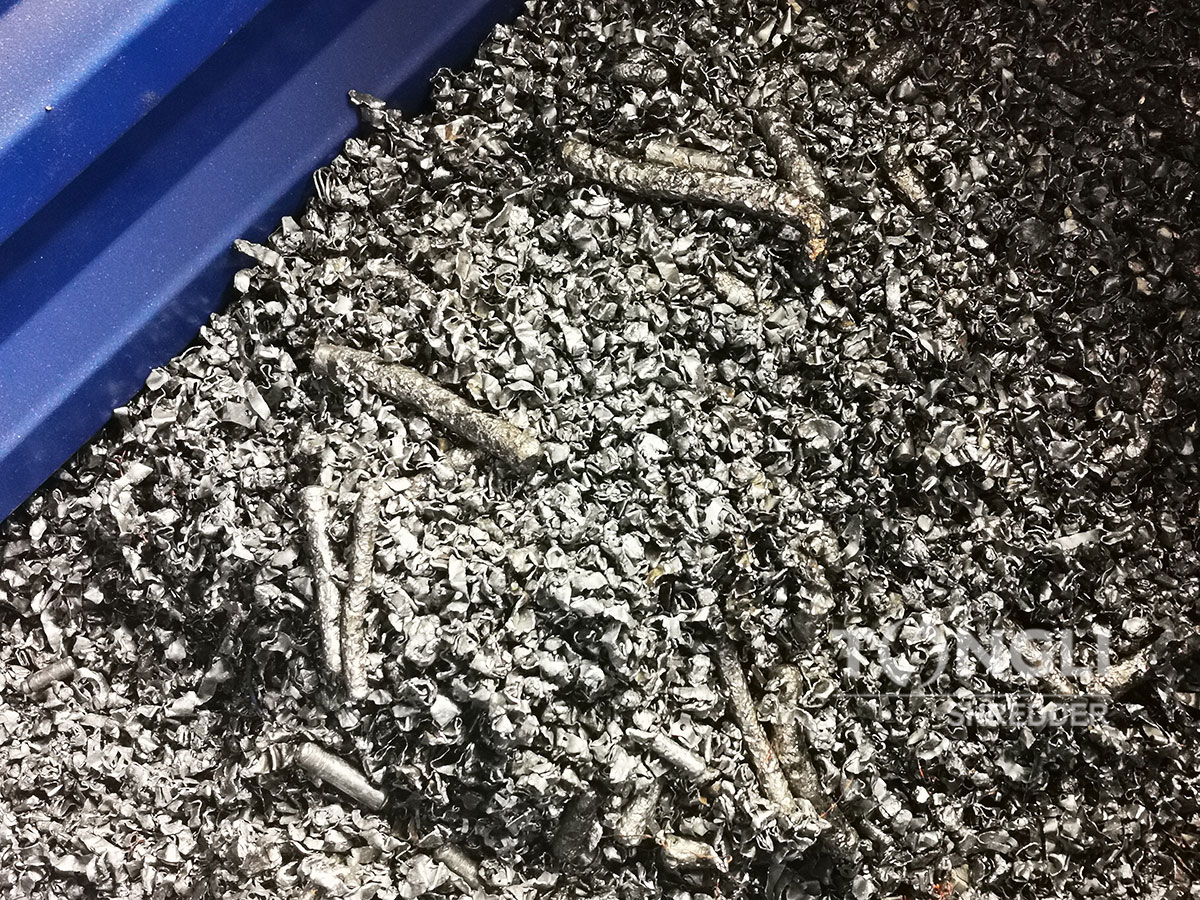

1. Transport the waste motor rotor to a vertical metal crusher for crushing. The crushed material is a mixture of iron and copper.

2. When the crusher is working, driven by the motor, the rotor rotates at a high speed. After the crushed material enters the crushing cavity, it is hit, collided, and shredded at high speed by several layers of wear-resistant hammers on the rotor during the falling process. After repeated rubbing and impacting, they are broken, rust, paint and other debris are gradually peeled off and discharged from the discharge port at the lower end; the broken mixture is sorted and stacked after passing through a conveyor and a magnetic separator.

3. A vertical crusher and a strong magnetic drum sorter are used to crush and sort waste motor rotors at one time. The size of the material crushed by the motor rotor crusher is determined by the screen in the crushing chamber, and the user's discharge requirements can be achieved through the size of the screen hole. After the motor rotor is crushed in the crushing chamber, uniform particles will flow out from the screen holes of the screen to complete the discharge.

After the workshop on-site test, the customer was very satisfied. After communicating the specific details and price with the sales staff, Khan signed the contract on the spot and paid the deposit for the factory to arrange production. The scrap motor rotor crusher has been in operation for three years, except for vulnerable parts, has been running well, and customer feedback is very good.

The continuous growth of the machinery market in recent years has also given new developments in the recycling industry, with more and more performance machinery products appearing in various recycling plants. Customer Khan plans to expand and crush more scrap metal. Due to the relatively large volume of some metals, our sales staff recommend that customers purchase another double-shaft shredder so that they can be used together. Small scrap metal can be directly put into a vertical crusher for crushing and sorting, and large scrap metal can be shredded by a dual-shaft shredder before crushing, so that scrap metal of various sizes can be crushed to meet customer needs.

Because of the previous cooperation, this time is a repurchase. After a comprehensive understanding of the double-shaft shredder, the customer Khan readily signed the contract and paid the deposit, and the factory is stepping up production.

Address :

Wanshan Rd., Xingyang, Zhengzhou,CHINAWhatsApp :

+86 132 1319 7820 (7x24h online)Phone :

+86(371)64693430E-Mail :

info@tonglishredder.com