WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

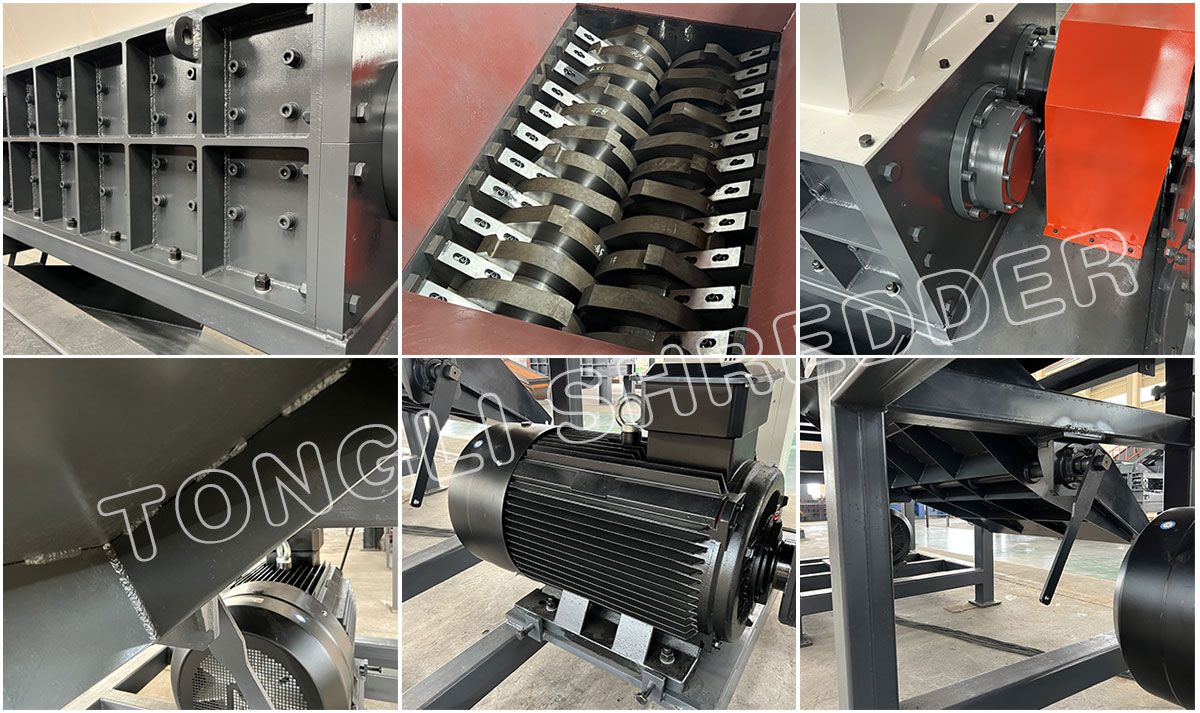

Yesterday, the double shaft shredder production line equipment customized by South African customer has been packed in TONGLI SHREDDER workshop and sent to the port. The twin shaft shredder is a machine used for coarse crushing, generally used to process various unprocessed raw materials or leftovers, making them smaller in size and convenient for transportation or subsequent processing. The shredded materials are then shredded and sorted to obtain clean metal particles. Compared with unprocessed metal materials, these crushed and sorted metal materials have higher sales prices and higher profits. Double shaft shredder equipment is widely used, the first choice for customers to buy.

Double shaft shredder, also known as shearing shredder, mechanical configuration includes: shredding blade set, carrying box, box support, feeding system, power system, electrical control system, through shearing, shredding and Squeeze to reduce the size of the material. When the double-shaft shredder is running, it relies on the motor to provide power, decelerates and increases the torque through the reducer and transmits it to the main shaft. There are two rolling shafts. For crushing, high efficiency coarse crushing with low energy consumption, and uniform granulation, in the production line operation, the medium volume material is crushed into small pieces by other equipment such as metal crushers. comparable advantages.

The double shaft shredder has low speed, high torque, stable operation, large crushing capacity, compact structure, low operating noise and less dust. It is widely used in scrap metal recycling, metal product processing, building materials, chemicals, electric power and other industrial sectors. Process all kinds of medium hardness metal materials with large volume and irregular shape, such as aluminum profiles, broken bridge aluminum, waste oil drums, pop-top cans, briquettes, etc. In addition to metal waste, it can also process wood, household waste, plastics, tires, waste cloth, etc.

The application scenarios of the double-shaft shredder generally include:

1. Shred materials of various volumes, hardness, sizes and shapes to improve material recovery efficiency and recovery value;

2. Shred metal scraps, some textile materials or unqualified products into smaller pieces for recycling;

3. Shred organic materials, wood and other materials to make biofuels and other materials.

According to the different types of recycled waste, the hardness and shape of metals in the current market, the dual-shaft shredder has been improved and optimized through various structures, and a series of different models, different types of claws, and mature and advanced technologies have been introduced. The pre-shredding of waste recycling and utilization provides reliable equipment for volume reduction treatment. The continuous flow of double-shaft shredder orders from customers can tell how popular it is.

Address :

Wanshan Rd., Xingyang, Zhengzhou,CHINAWhatsApp :

+86 132 1319 7820 (7x24h online)Phone :

+86(371)64693430E-Mail :

info@tonglishredder.com