WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

With the development of science and technology and the needs of life, the speed, safety and convenience of electric kettles have become the main features. People who like to drink tea have fallen in love with it and become a best-selling product in the world. If it is used, it will be eliminated. In the face of a large number of accumulated waste electric kettles, how to recycle? Small vertical crushing production line is more suitable.

The small vertical crusher is one of the most cost-effective models in the crusher, with fast discharge and good taste of the finished material. This small vertical crushing production line introduced to you today is specially used for crushing waste electric kettles, so that you can produce like a duck in water in the small production line, spend the least amount of money, and achieve the effect you want.

It can be seen from the video that the waste electric kettle is transported to a small vertical crusher by a bucket belt conveyor for crushing. The crushed materials are sorted out by a magnetic drum to select a part of ferrous metals, and the remaining materials are then passed through the second magnetic drum below. Secondary sorting, non-ferrous metals and ferrous metals are obtained, and the sorting rate can reach 99%.

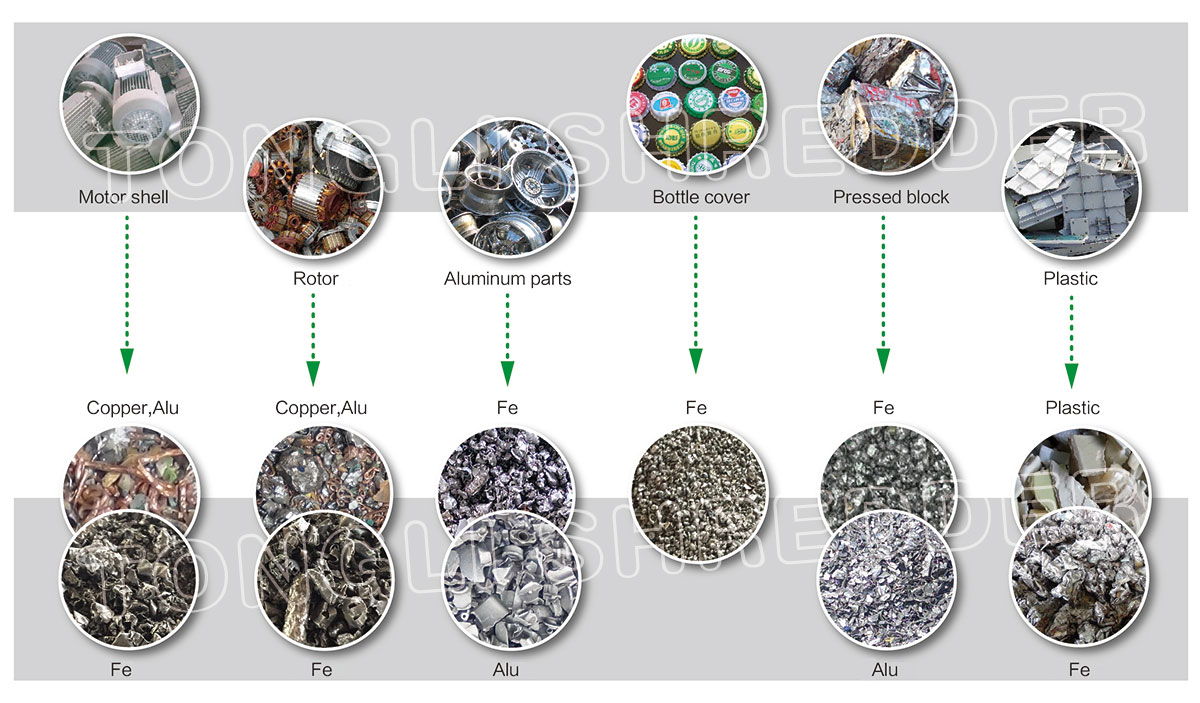

This small vertical crushing production line can not only crush electric kettles, but also crush metal materials such as stators, rotors, aluminum slag, raw aluminum, hardware, carton nails, etc. It is mainly used for small-scale crushing production. Adjustable, can provide a large amount of high-quality material in a short time.

Vertical crusher is a combination of similar metal crushing technologies at home and abroad, and has the advantages of impact crushing and hammer crushing. The new type of fine crushing and coarse grinding products are developed by optimizing the main technical parameters. The vertical crusher has no screen bar design, so that the material can be discharged from the discharge port smoothly, which not only reduces the wear and tear of the machine, but also does not cause production. During the process, the congestion caused by too much feeding greatly improves the productivity. The vertical crusher is mainly used for medium and small crushing raw steel scrap, clinker, and other medium and hard recycled materials such as scrap iron, scrap aluminum, plastic, rubber, etc. It has the characteristics of large crushing ratio, low energy consumption, stable operation, simple structure, convenient operation and maintenance, etc. It is a truly multi-purpose, high-efficiency and low-cost new type of crushing equipment.

If you have limited funds and want to choose a cost-effective crushing production line, you can consider a vertical crusher. The quotation of the vertical crusher is among the "Great God-level" crushers, which is very economical and cost-effective, and can be purchased at a starting price of tens of thousands of yuan. And it is very cost-effective for small crushing production cases, you deserve it!

Address :

Wanshan Rd., Xingyang, Zhengzhou,CHINAWhatsApp :

+86 132 1319 7820 (7x24h online)Phone :

+86(371)64693430E-Mail :

info@tonglishredder.com