WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

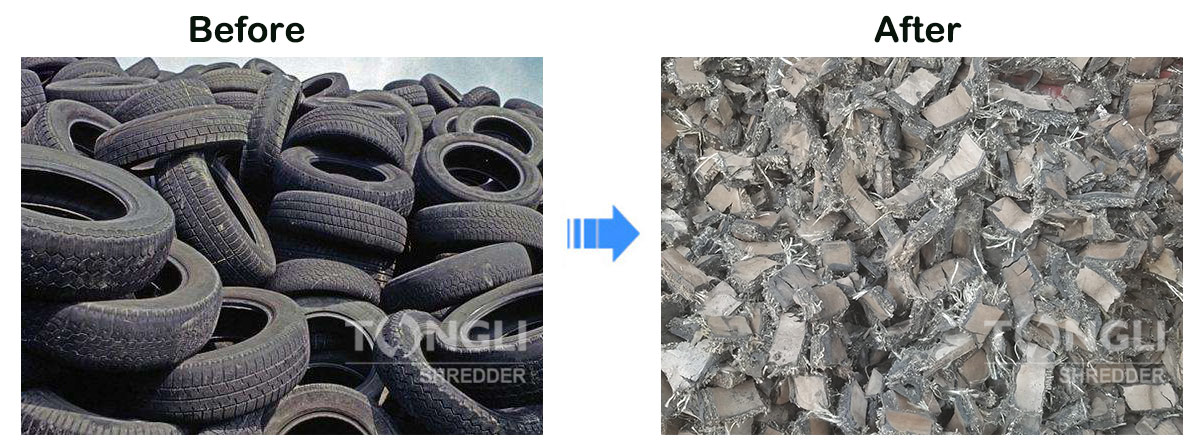

In recent years, with the rapid development of automobile, raw rubber is becoming increasingly scarce. How to effectively use scrap tires has become a problem to be solved all over the world. Some waste tires are sawn into small pieces by hand and then broken, which is very inefficient; Some buy expensive and inefficient equipment, and the investment cost is too high, which is not a good way to recycle waste tires economically and effectively. After several years of painstaking research and development and learning from the experience of similar products, Zhengzhou KAMO has successfully developed a tire shredding production line through continuous improvement. The equipment has convenient operation and high production efficiency. It can effectively deal with all kinds of waste tires and achieve the purpose of secondary recycling.

The advent of tire shredder has successfully solved the problem that it is difficult to deal with waste tires. The shredded tires can be recycled directly or combined with shredder to split them into small particles without any pollution. At the same time, the steel wire and fiber in the waste tires are separated, making the waste tires become the "black gold" of renewable resources, The utilization value is greatly improved. So for rubber processing manufacturers, how to choose a suitable tire shredding production line?

1. Select the right manufacturer. It is very important to choose the manufacturer of tire shredder. Good manufacturers not only have complete models, but also customize appropriate schemes according to the actual needs of customers and provide the best production line, so that customers can spend every penny on the blade.

2. Purchase equipment according to the output. Customers should first estimate the daily raw materials and output, and then select the appropriate shredder production line according to the output. If the budget is sufficient, they can also choose a set of production line with a slightly larger output in case of emergency.

3. Don't follow blindly. Net red products with good sales are not necessarily the most suitable for themselves. Customers should choose and buy according to their actual needs, material size, quantity and output, rather than what others buy. If they blindly follow the trend, they will lose a lot if they buy inappropriate equipment.

4. One price and one goods. We can't just try to be cheap without looking at quality. Some customers only pay attention to the equipment price and buy the equipment with lower price. In this way, they will only be deceived. Either the equipment is not installed well, or there are often problems during operation, affecting the production. Therefore, the price is on the one hand, and the quality of the product is also very important.

5. Choose the time. The price of tire shredding production line will also be affected by raw materials and sea freight. If customers decide to purchase, they should make preparations in advance and always pay attention to the price of domestic steel and sea freight, so as to buy the most satisfactory equipment at the most favorable price.

The above are the major factors in choosing a suitable tire shredding production line. The current rubber market is soaring all the way, which is a good time to show your skills. Customers who want to buy a tire shredding production line should call to order quickly!

Address :

Wanshan Rd., Xingyang, Zhengzhou,CHINAWhatsApp :

+86 132 1319 7820 (7x24h online)Phone :

+86(371)64693430E-Mail :

info@tonglishredder.com