WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

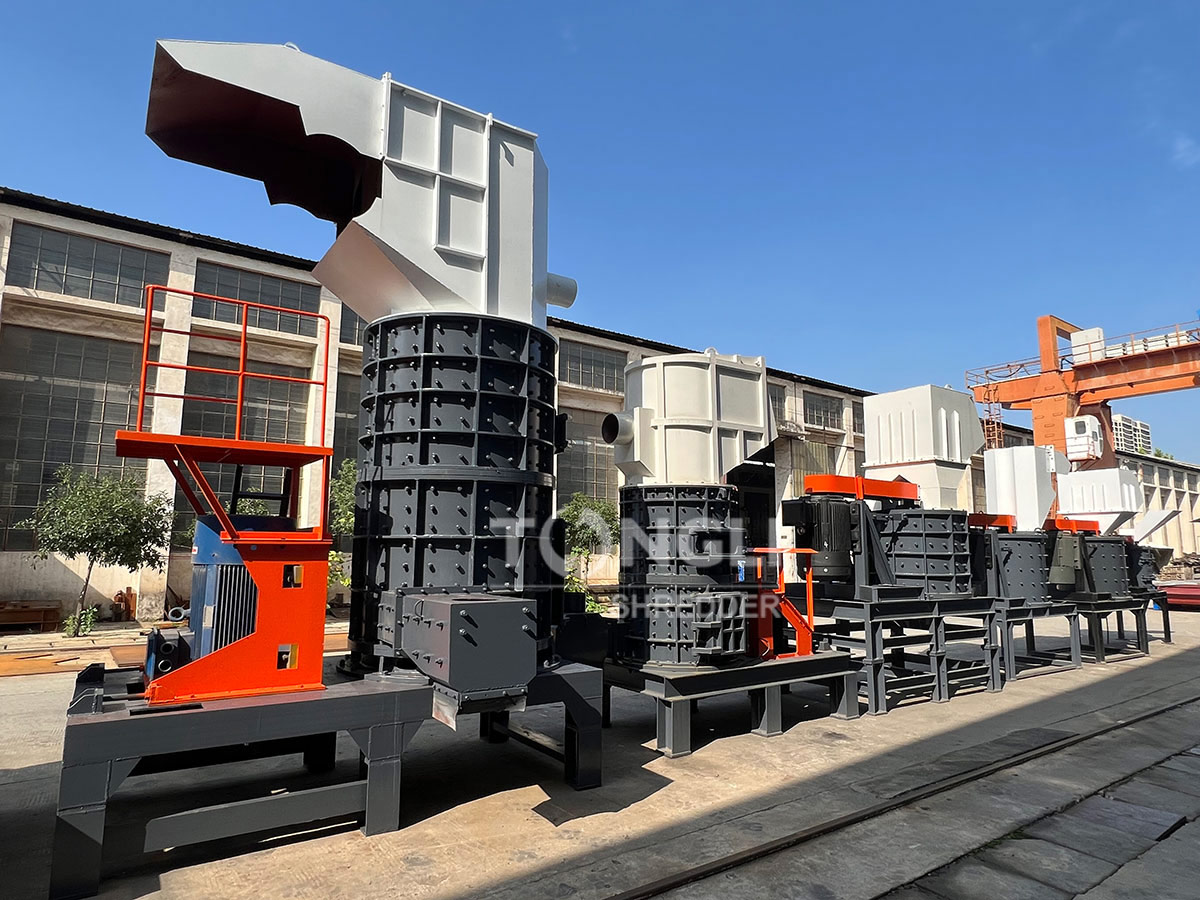

Entering the TONGLI SHREDDER workshop, you can see the large medium small new vertical hammer mill crushers are placed neatly next to each other, some of which are customized by customers, and a small amount is available as workshop inventory. The main raw materials crushed by the new vertical crusher are all kinds of metals, such as waste household appliances, briquette, bicycles, paint buckets, cans, etc. After processing, waste is turned into treasure, and the crushed metal particles can reduce transportation costs and increase investment. The efficiency of furnace ironmaking plays an irreplaceable role in deoxidation or metal processing in steel mills. It has the advantages of small investment, fast recovery of funds, wide sales, energy saving and environmental protection, etc. It is a new environmental protection project that is vigorously supported and implemented by the world.

TONGLI SHREDDER vertical crusher adopts domestic patent technology of kneading and crushing (invention patent, plagiarism must be investigated). Because of its advanced technology, large processing range and high productivity, the vertical crusher can also sort out non-ferrous metals, remove non-metallic debris, and process high-quality scrap steel with high purity, and it has less environmental pollution during processing. Known as the current scrap processing equipment with great potential. The crushing machine is the core part of the vertical crusher. Its research and development are of great significance to improve the level and quality of the utilization of scrap iron and steel in my country and to realize the upgrading of metal recycling and processing equipment in my country.

The working principle of the vertical crusher is to use the basic principle of hammering. The scrap steel from the chain conveyor falls into the scrap steel feeder, and enters the vertical crusher after the push-pull of the feed roller and the extrusion of the shaping roller. Driven by a high-speed and high-torque motor, the rotor of the vertical crusher uses the hammer heads distributed along the circumference and the axial direction to hit the scrap steel entering the crushing cavity in turn. Tear into pieces that meet the design requirements.

Features of the new vertical crusher:

1. The vertical crusher has a large crushing ratio, and the crushing ratio can reach the discharge particle size and can be adjusted arbitrarily, and is not affected by the wear of the plate hammer and the lining plate;

2. The vertical crusher is a multi-stage crushing optimized and designed on the basis of absorbing domestic and foreign fine crushing equipment. It is divided into coarse crushing and fine crushing, and the discharge particle size is controllable;

3. With no screen design, it is not easy to block when crushing materials with high moisture content and large mud content. The elastic adjustment mechanism is adopted, and the unbreakable materials can be automatically discharged without causing damage to the design;

4. Consumables are made of high-hardness, high-toughness multi-element alloy wear-resistant materials, with less wear and long service life. The distance between the hammer head and the impact plate can be fine-tuned to ensure uniform product particle size. The hammer head can be used in reverse, the utilization rate of the hammer head is greatly improved, and the service life is increased by about 5 times;

5. The rotor body of this machine has a unique structure, and the rotor body hardly wears when crushing materials. The rear cavity is provided with a screw rod or a hydraulic opening mechanism, and the wearing parts can be easily replaced without starting the main equipment. Smooth operation, low noise, small vibration and good sealing. Easy to operate, small footprint, easy installation and maintenance.

The new vertical metal crusher designed by TONGLI SHREDDER has solved the troublesome and time-consuming maintenance of the old equipment in the past. The unique displacement adjustment technology, the hammer head does not need to be repaired after wear, and the moving position is used repeatedly. One pair of hammer heads can top three pairs of ordinary hammer heads. Hydraulic electric starter case, only one person to operate, light and fast, saving labor and time, and easy to maintain. The new vertical metal crusher is simpler and more convenient to operate, and the output and fineness are relatively greatly improved. Based on the old crushing equipment, it has been continuously explored and improved, which greatly reduces the cost of the equipment. Compared with the product The price is also more reasonable.

Address :

Wanshan Rd., Xingyang, Zhengzhou,CHINAWhatsApp :

+86 132 1319 7820 (7x24h online)Phone :

+86(371)64693430E-Mail :

info@tonglishredder.com