WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

The arrival of spring makes everything green, and the emergence of metal crushers and supporting equipment also brings vitality to the waste resource recycling industry. Whether it is from the perspective of metal resource recovery and reuse, or from the perspective of beneficial disposal of large-scale waste, the advent of metal crushers and supporting equipment has many benefits. Scrap metal resources are unlimited and have broad development prospects. Metal shredders can help you reuse waste products and create huge profit margins for you. Generally, funds can basically be returned within one year after purchasing metal shredders and supporting equipment.

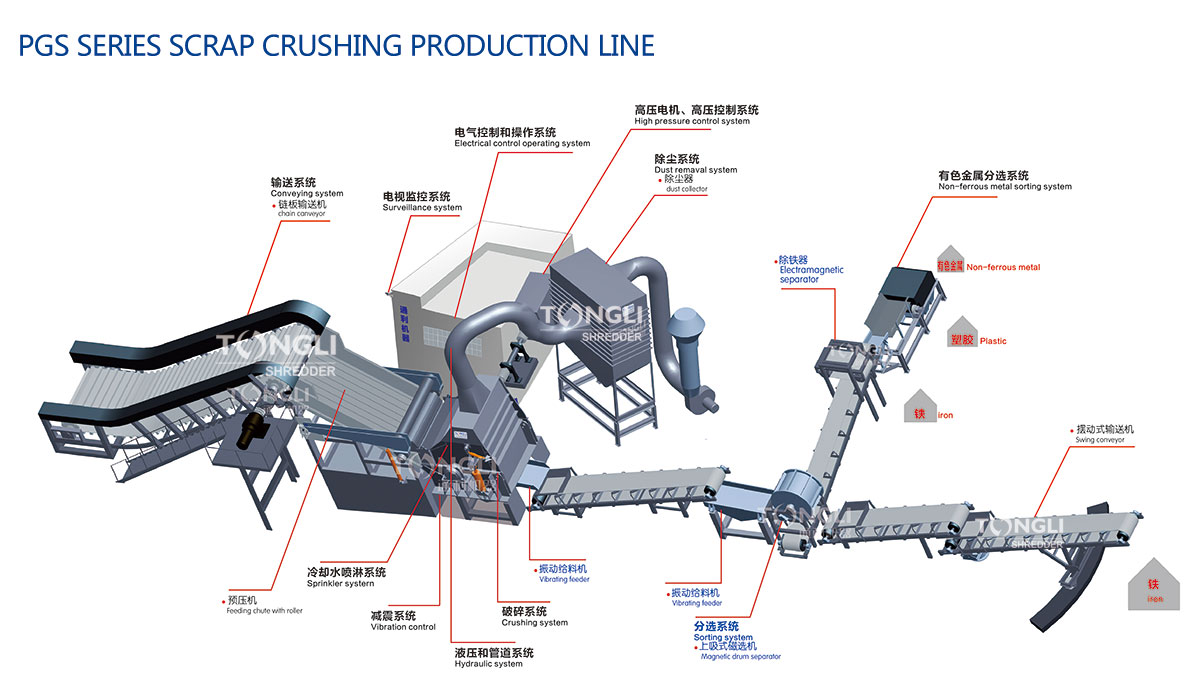

The metal crusher and supporting equipment are shown in the following figure:

Process flow:

1. The scrap metal shredder is the core equipment for the crushing, sorting and recycling of various scrap metal materials, scrap aluminum, paint buckets and other scrap metal materials. Crusher host;

2. Driven by a high-speed and high-torque motor, the rotor of the scrap metal crusher smashes and crushes the scrap metal strongly. Through the space formed between the counterattack lining plate and the hammer head, the material to be crushed is hit and rubbed back and forth to form a spherical metal These metal particles obtain kinetic energy from the hammer head. When the volume of the material is smaller than the pore size of the sieve plate, it will be automatically discharged. The scrap metal larger than the pore size will continue to be kneaded and crushed on the sieve plate until the volume reaches a suitable particle size;

3. The crushed metal particles are sent out through the conveyor belt, and then the material is separated from ferrous metal and non-ferrous metal by a magnetic separator. If the material contains aluminum metal, it should be used in conjunction with an aluminum jumper to achieve multiple separation of metals. , maximize the sorting of metals and improve the recycling value. In fact, in the process of scrap metal crushing, impurities such as rust and paint on the metal surface will be separated by multiple shocks and vibrations, which greatly improves the cleanliness and purity of the materials.

Waste recycling is a topic that is much talked about in today's society, including wastes from all walks of life, waste plastics, and scrap metals. Iron products or construction iron can also be sent to steel mills for refurbishment.

According to market conditions, sales of metal crushers and supporting equipment are stable in a short period of time, and prices continue to rise. If you want to invest in metal crushers now, profit margins will continue to increase. As a metal resource regeneration and crushing equipment, metal crusher adopts new automatic control technology in manufacturing and processing technology, which can provide industry investors with more economical production. The metal crusher developed and produced by TONGLI SHREDDER has the advantages of large crushing ratio, uniform crushing material, wide application range, high degree of product automation, and complete models. After crushing, the crushed material has the advantages of less paint impurities, high material density and high separation rate of different materials.

In the increasingly fierce market competition, productivity plays an important role, and the possession of advanced science and technology is a solid foundation for the continuous innovation and development of manufacturers. While developing the economy, we cannot ignore the concept of environmental protection. Metal crushers and supporting equipment take both sides into consideration, which not only promotes economic development, but also realizes the recycling of resources and takes a model of sustainable development.

Address :

Wanshan Rd., Xingyang, Zhengzhou,CHINAWhatsApp :

+86 132 1319 7820 (7x24h online)Phone :

+86(371)64693430E-Mail :

info@tonglishredder.com