WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

Last week, a customer entered the official website, added WhatsApp for sales, and consulted on scrap metal crushers. Because we have more models, we have communicated with customers many times. After the customer has a general understanding of metal crushers and metal shredders, they He recommended a plan of tearing first and then breaking. In fact, they are all related products. Metal shredders are used in the early stage of waste recycling and can be used with crushers.

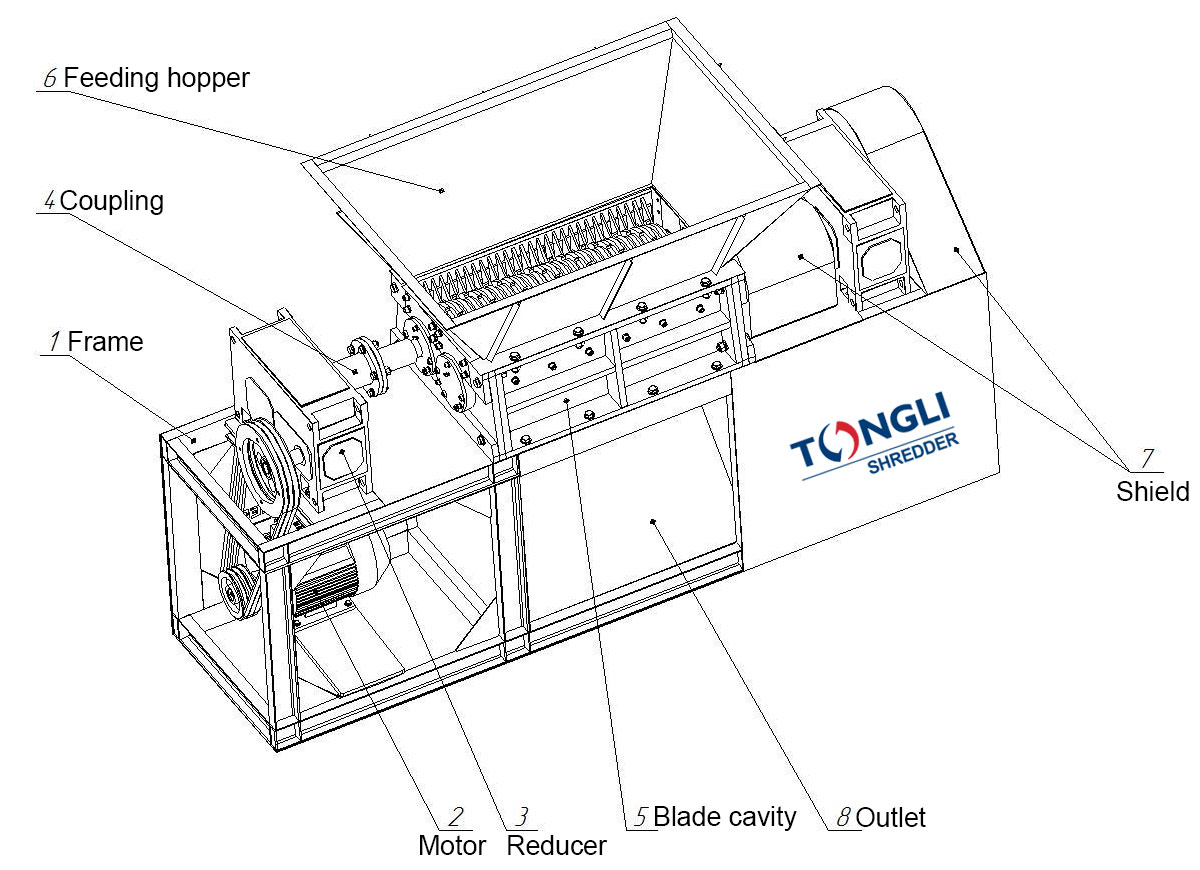

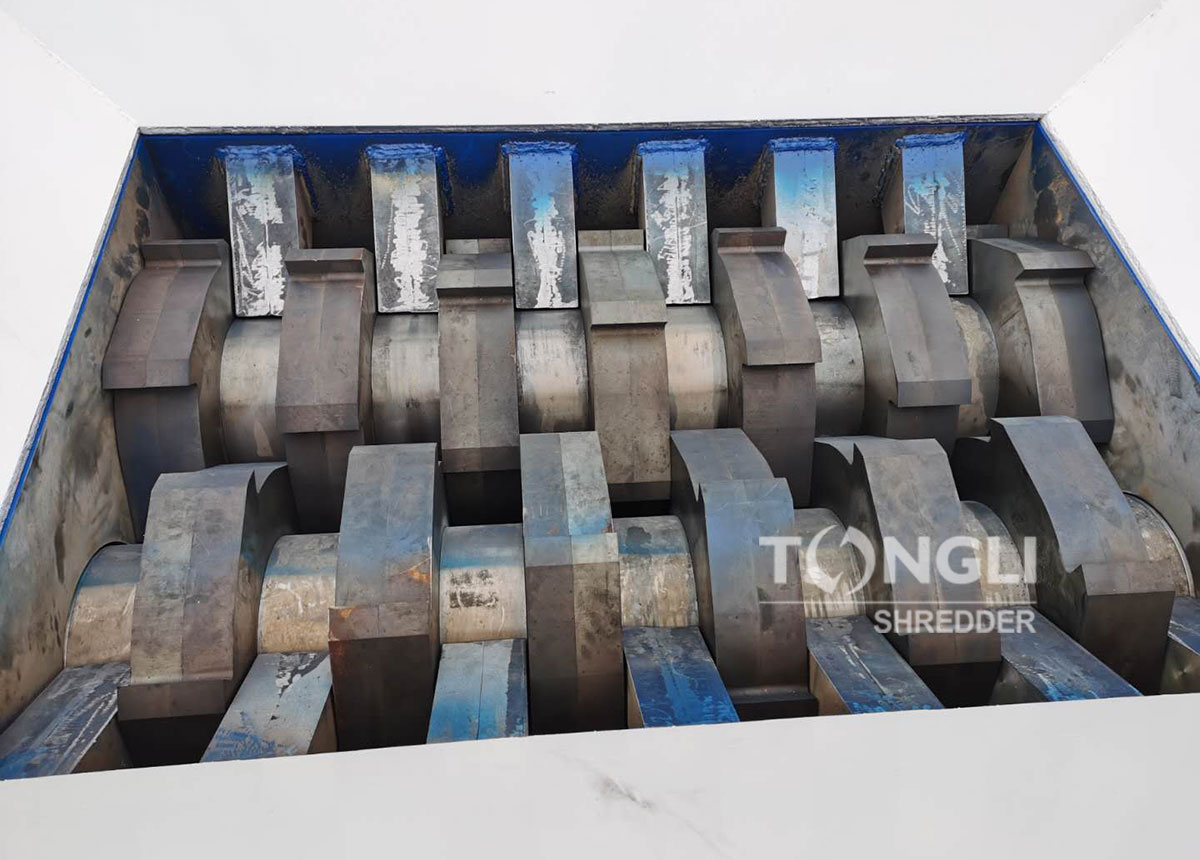

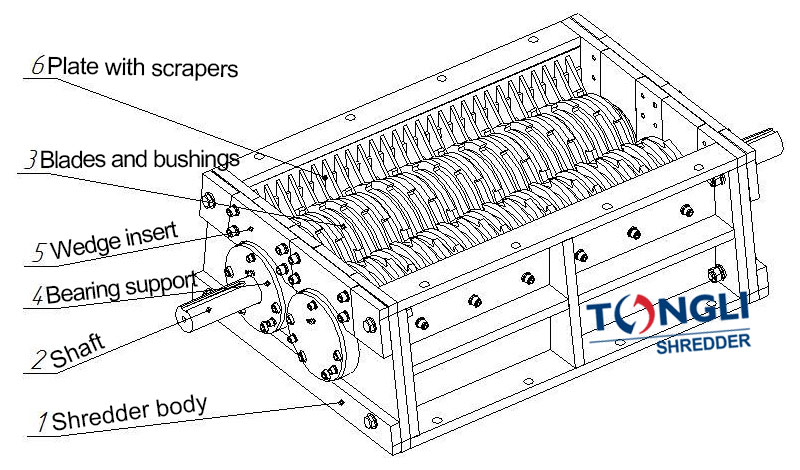

The metal shredder is also known as the shearing shredder, which reduces the size of the material through cutting, tearing and squeezing. The thickness of the knife and the number of claws can be changed according to different materials. When crushing hollow materials, a pressing device can be equipped to increase the output, and a rotating screen can also be added to control the size of the discharge. Therefore, during production, the material will be pressed accordingly to achieve the automatic feeding function. The unique tool shaft structure and four-corner rotary tool will prevent the shaft from being wound or jammed during the production process with low speed and high torque. This phenomenon improves production efficiency. This equipment is suitable for crushing various materials with high toughness and viscosity.

The metal shredder promotes the development of the waste recycling industry and can meet the waste recycling requirements of various industries. It is suitable for shredding thick and difficult to shred materials, such as: electronic waste, plastic, metal, wood, waste rubber, packaging barrels, pallets, etc. There are many types of recyclable materials, and the shredded materials can be recycled directly or further refined according to requirements. It is suitable for industrial waste recycling, medical recycling, electronics manufacturing, pallet manufacturing, wood processing, household garbage recycling, plastic recycling, tire recycling, paper making and other industries. The metal shredder has the characteristics of large torque and low noise. It adopts a PLC control system and can be automatically controlled. It is equipped with start, stop, reverse and overload automatic reverse control functions.

The main performance characteristics of the metal shredder:

1. It has small size, light weight, low noise, and is very convenient for installation and maintenance;

2. The structure size of the toothed roller is designed according to the product granularity requirements. After the broken tooth is worn out, the broken tooth can be directly replaced on site, which greatly reduces the use cost;

3. Very low over-crushing. Using the shearing principle, materials smaller than the required particle size are directly passed through, and materials larger than the particle size requirements are crushed, avoiding the defects of materials entering the crusher from being mixed and broken. For medium-hard materials such as coal and coke, the over-crushing rate is generally below 5%.

The metal shredder produced by Henan Tongli united with universities and colleges uses alloying ratio and automatic control technology to meet customers' requirements for equipment performance. The scrap metal recycling and processing industry is different from other electronics industries or fast-moving goods industries. Metal is the cornerstone of the development of our nationals. If you want to invest in this industry, you need to pay more attention to policy changes and trends, and grasp the upsurge of the waste recycling and processing industry. When the peak season comes, step up production, look for stable sales channels, and make a fortune.

Address :

Wanshan Rd., Xingyang, Zhengzhou,CHINAWhatsApp :

+86 132 1319 7820 (7x24h online)Phone :

+86(371)64693430E-Mail :

info@tonglishredder.com