WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

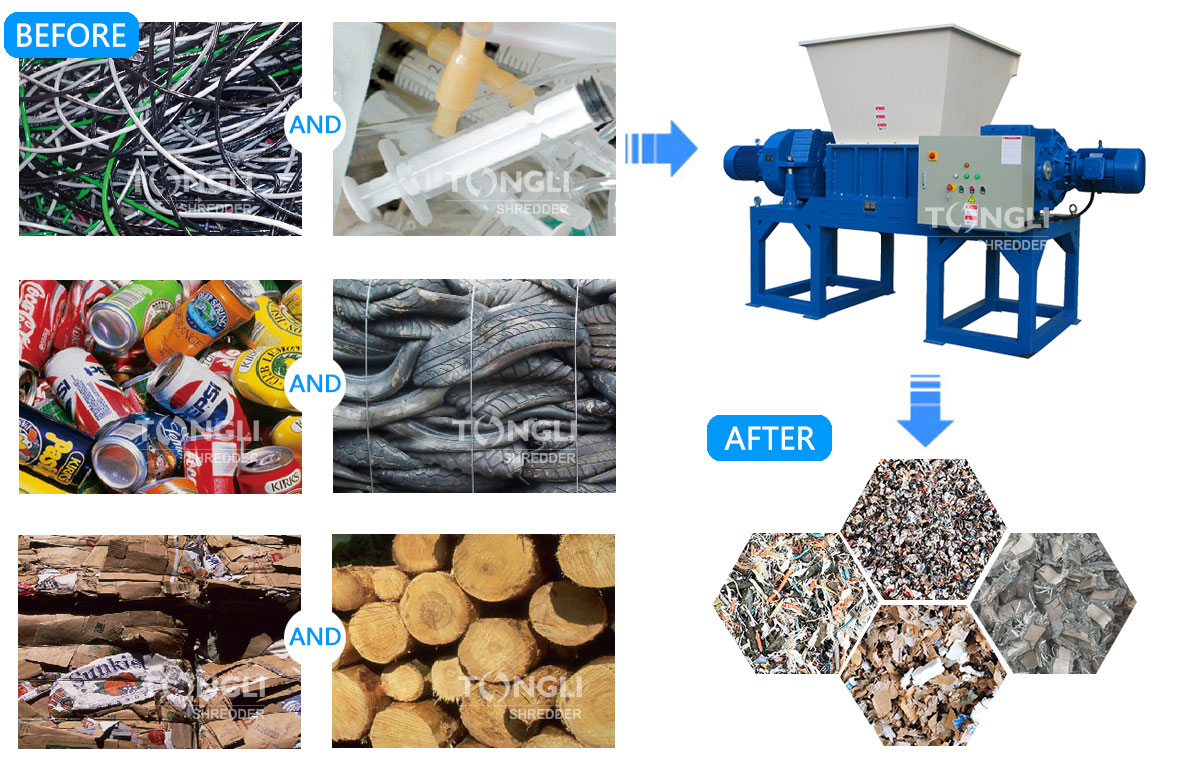

The global annual production of scrap metal materials is increasing year by year, which is an inestimable market. After scrap iron recycling resources are scrapped, shredded, and returned to the furnace to make steel, the waste can be reused, with broad development prospects and large profit margins. Metal shredder is the general name of these shredding various metal equipments. There are various models of large, medium and small. The metal materials that can be processed include: scrap car bodies, scrap steel, scrap iron, scrap aluminum, scrap household appliances, generators, color steel tiles , paint buckets, cans, iron filings, etc. The processed materials can be used as raw materials for steelmaking, reducing transportation costs.

Metal shredders are commonly used in waste collection stations, recycling markets, industrial waste, and domestic waste treatment, with prices ranging from tens of thousands to millions of yuan. It is also called a multifunctional shredder in the market. Rubber, wood, pipe and other bulky waste. The metal shredder can be customized and matched according to the needs of customers. The higher the demand, the higher the price. The metal shredder coupling is a non-welding one-time forming equipment made of special material technology, which meets the current production standards of environmental protection and energy saving in the market, and has a high yield in production.

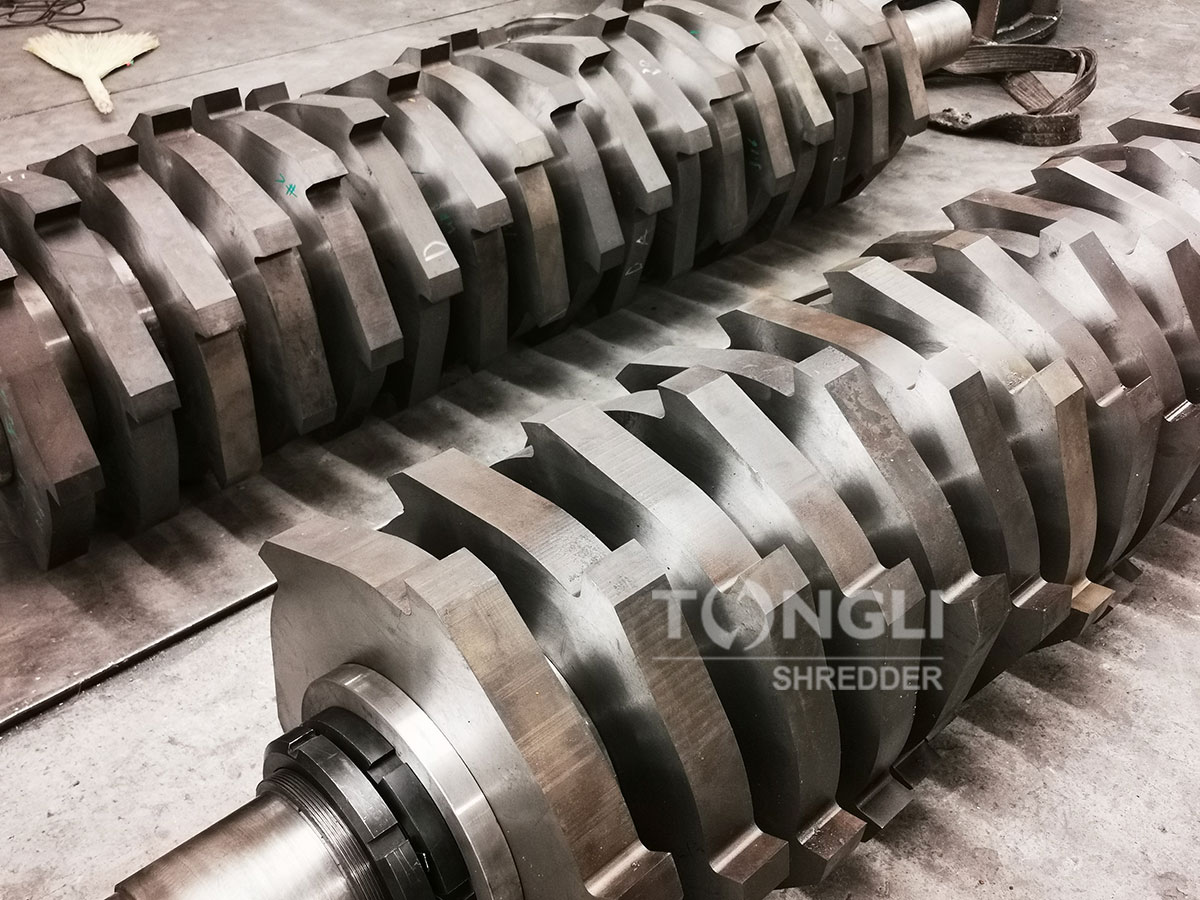

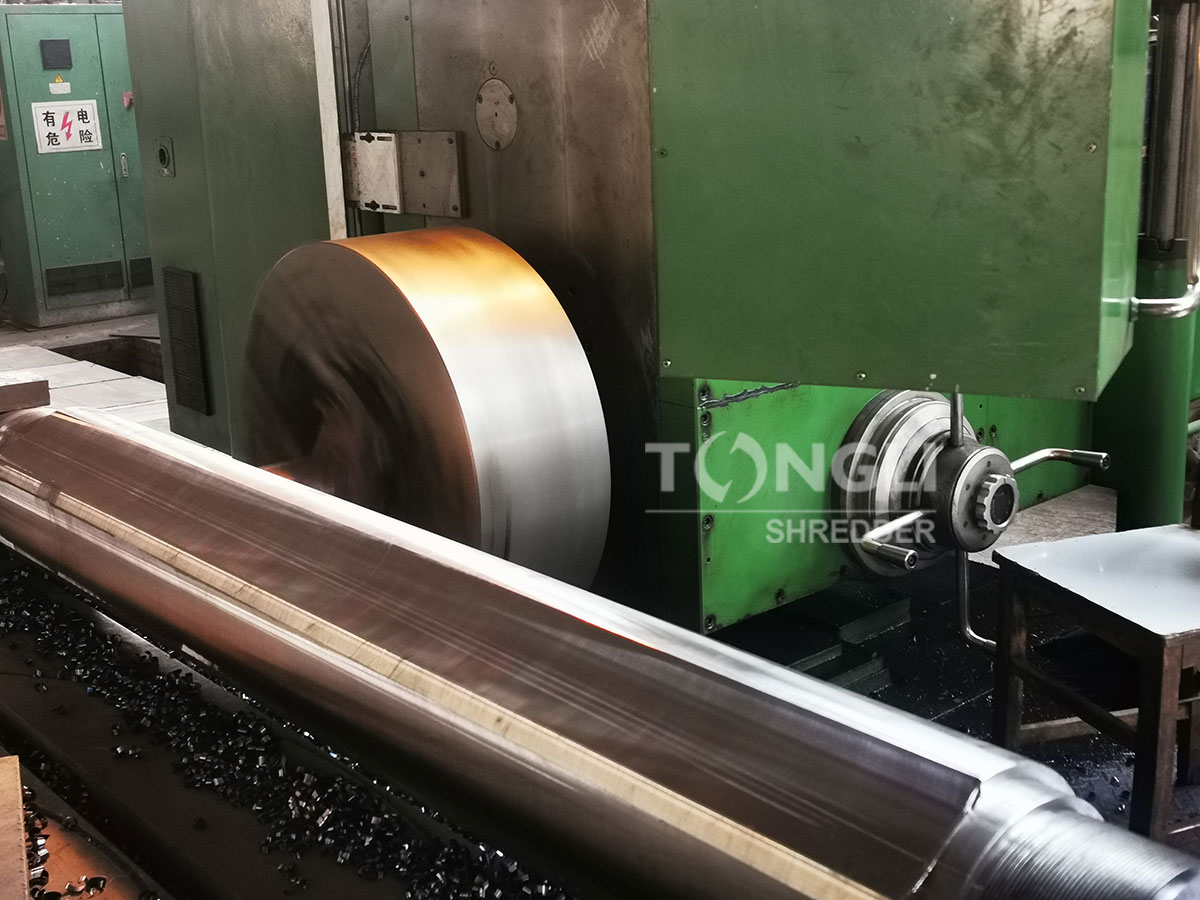

What size material can the metal shredder handle? Metal shredders are popular for their high transmission efficiency, smooth operation and low noise. The low-speed operation reducer configured on the metal shredder is driven by a hard-surface cylindrical gear reducer, with strong power. The blade is forged with special alloy tool steel and made by multiple heat treatments, which has strong wear resistance and strength. Has the ability to repair multiple uses. The metal shredder equipment can handle large-scale raw materials, using a combination frame precision machined with thickened steel plates, a large-angle strong rotating shaft, and long-sized materials can enter the large feeding port for shredding work. The feeding of the metal shredder can be assisted by a feeding conveyor or a chain conveyor. The feeding problem of the metal shredder matches the equipment model. The larger the model, the larger the feeding port, and the shredded material is also comprehensive. In addition, different blades can be selected for production for different materials.

The metal shredder can provide reasonable solutions for different customer sites, and choose what type of shredder for what material to handle. The hardness, size, and shredding specifications of each material are different, and the shredder model is also different. There are no restrictions on investment in metal shredders, hundreds of thousands to millions of dollars can be invested, depending on the scale of processing, such as processed iron products can be sent to steel mills for refurbishment, becoming the iron concentrate needed in the market Mine and recycled iron form processable renewable resources, such as paper clips and fish hooks that are common in life, are processed from scrap iron.

The same is true for scrap aluminum. Scrap aluminum products can be recycled into recycled aluminum, which is an important part of production. After removing the impurities by heating and melting, physical and chemical methods, and making various grades of aluminum, it is beneficial to the production and regeneration of metal aluminum. In the production of scrap metal, an eddy current separator is usually configured, which can evenly separate impurities such as scrap aluminum and scrap plastic.

After being shredded, scrap steel can be used as raw material for steelmaking, with large output and high efficiency, and can be directly fed to reduce transportation costs. The advantages are mainly reflected in cost saving, energy saving and environmental protection and energy saving. Due to different material processing conditions, metal shredders can be purchased with single-shaft, double-shaft and four-shaft shredders. Customers are welcome to come and visit!

Address :

Wanshan Rd., Xingyang, Zhengzhou,CHINAWhatsApp :

+86 132 1319 7820 (7x24h online)Phone :

+86(371)64693430E-Mail :

info@tonglishredder.com