WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

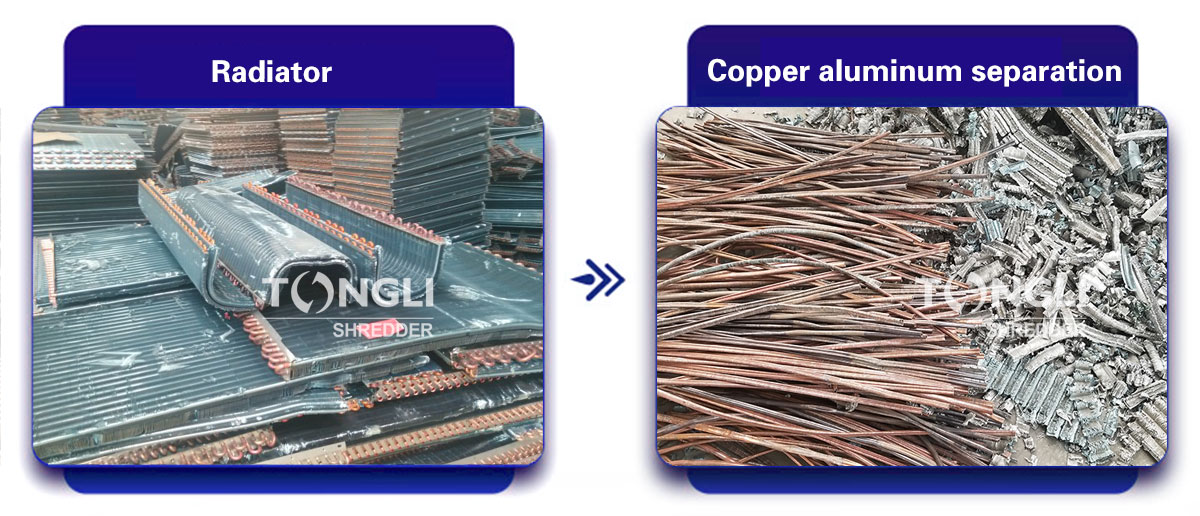

With economic development, there are more and more scrap copper and aluminum radiators in various regions of the world. Whether it is AC radiator, car radiator, or heating radiator, they are all composed of copper and aluminum, and the content of copper pipes is more than 97%. Radiator Copper Aluminum Separation Machine is used to separate the copper and aluminum in the waste radiator, and does not damage the copper and aluminum, and has no powder. One machine has multiple functions, all radiators of different sizes can be used on one machine, with fast speed, low cost and high efficiency.

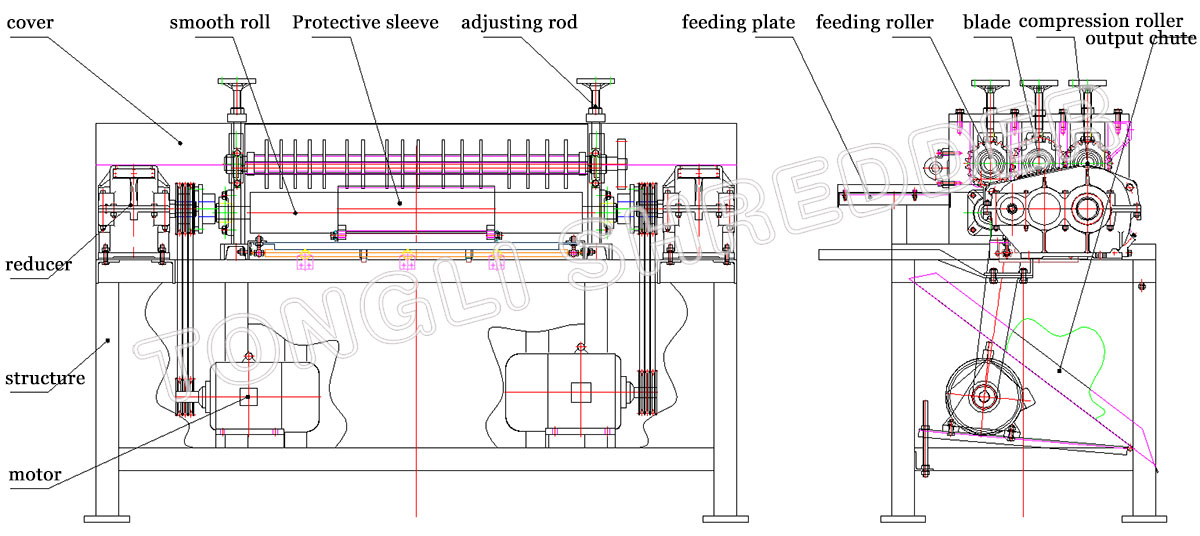

Radiator Copper Aluminum Separation Machine is consisted of a frame, two motors, two speed reducers, material feeding part, material cutting part, material separation part, transmission part and material feeding panel. The processing range is 19mm, 21mm, 25mm, non-standard products can also be customized according to customer needs. The electrical control system includes motor's positive and negative rotation start, stop and emergency stop buttons. The machine can be used single or matched with the band saw machine. And it's with features of easy operation,save labor and large market prospect.

Having said that, let's talk about the band saw machine. It is a machine before the operation of the radiator copper aluminum separation machine. It first cuts the waste radiator into regular shapes, and then uses the radiator separator to separate the copper and aluminum. Tongli band saw machine is an improvement on the basis of woodworking band saw machine. It is a common machine for furniture manufacturing and solid wood processing. It is not only suitable for wood cutting and sawing, but also for cutting wood obliquely into a certain angle.

Working principle:

The motor is driven by the belt to drive the high-speed shaft of the reducer, and the low-speed shaft of the reducer drives the main shaft to rotate through the coupling, and drives the feed roller, knife roller set and pressure roller set to rotate through the gear set installed at both ends of the main shaft; the band saw is cut. The radiator material is put into the corresponding feeding platform according to the specifications, and guided forward under the action of the feeding roller. The upper and lower knife rollers rotate to cut the upper and lower aluminum layers of the copper pipe of the radiator, and then the copper tube and the aluminum layer are separated under the action of the pressure roller.

Process control:

1. Arrange all the materials cut by the band saw machine into a straight line, and adjust the machine according to the processed material (19/21/25mm)

2. Turn on the electric control, check whether it is normal if there is no feeding in about 1 minute, if everything is normal, start feeding.

3. According to the production situation, finely adjust the feeding roller and blade to keep the production stable and the copper and aluminum are separated cleanly.

4. According to the production situation, properly fine-tune the feeding roller, knife roller group and pressure roller group to ensure stable production and clean separation of the copper tube and aluminum layer.

5. During the production process, do not touch the cover to prevent any accidents.

6. If abnormal sound or violent vibration is found during the production process, stop feeding, cut off the power supply, press the emergency button, check the machine, and eliminate the fault after the standby unit is completely stopped. Press the emergency stop switch when restarting the machine

7. If you change the material of a different size, you must clean the prefabricated material first, and then start the radiator of the new size.

The radiator copper aluminum separation machine is a very popular product and is deeply loved by customers. If you are also interested in radiator copper aluminum separation machines and band saw machines, please contact us!

Address :

Wanshan Rd., Xingyang, Zhengzhou,CHINAWhatsApp :

+86 132 1319 7820 (7x24h online)Phone :

+86(371)64693430E-Mail :

info@tonglishredder.com