WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

There are many types of shredders, including single shaft shredders, double shaft shredders and four shaft shredders. The single shaft shredder can meet the waste recycling requirements of various industries and is suitable for recycling plastics, paper, wood, fiber, rubber, domestic waste, etc., with a wide range of recyclable materials. The single-shaft shredder is suitable for recycling various large solid materials, difficult-to-handle materials, plastic containers, plastic barrels, and plastic pads. The discharge size can be as small as 20mm according to different needs. And various feeding hoppers can be provided according to customer needs. This equipment has low-speed rotary cutter, low noise and is more energy-saving.

The working principle of the single shaft shredder is that the material enters the chassis from the feed hopper. The pushing box pushes the material to the rotating knife roller under the push of the hydraulic cylinder. The rotating knife and fixed knife crush the material, and the broken material passes through the screen. Fall, and then transported to the next process or collection and packaging through auxiliary conveying equipment.

The material enters the shredding box through the feeding system. The box carries the shredding blade. The pushing box pushes the material to the vicinity of the blade. The material is shredded into pieces through the comprehensive action of tearing, squeezing, and shearing of the shredding blade. Small pieces of material are discharged from the screen holes.

TONGLI SHERDDER single shaft shredders have many advantages and features:

1. The blade is made of cold work die steel. The blade body has good strength, high toughness and high cutting performance. The blade has four cutting edges and can be rotated 90° after wear and continues to be used.

2. External bearing design is waterproof and dustproof, extending the service life of the bearing.

3. Hydraulic forced feeding, the speed is stable and adjustable, and the propulsion force is large and uniform.

4. Hard tooth surface reducer, high transmission efficiency, strong load-bearing capacity and low noise.

5. The blade spacing and rotation speed can be adjusted to adapt to the processing needs of different materials. By adjusting these parameters, the desired shredding effect and particle size can be obtained.

6. Powerful shredding ability, able to quickly and efficiently cut materials into required sizes. This helps reduce material volume and facilitates subsequent handling and transportation.

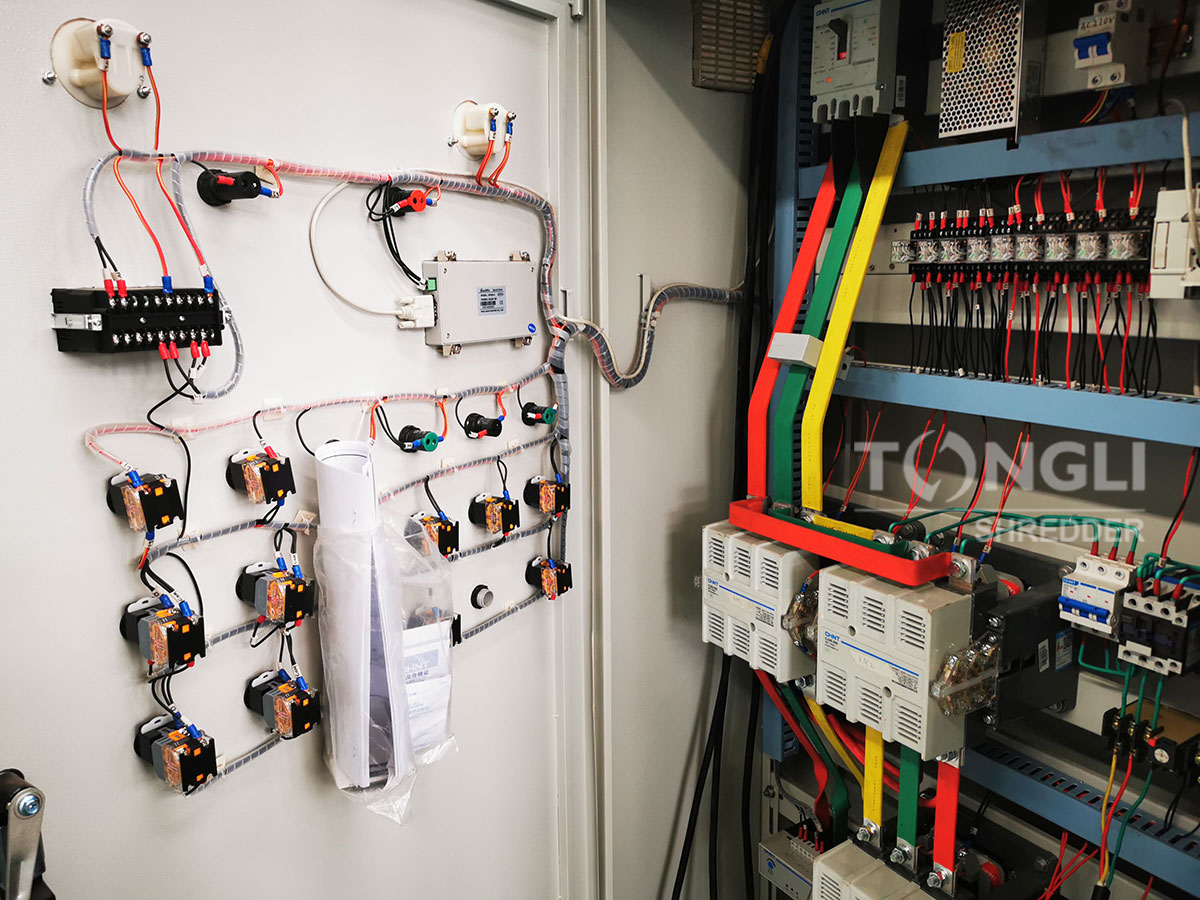

7. Equipped with safety devices such as protective covers, emergency stop buttons and overload protection devices to ensure the safety of operators and the reliability of equipment.

The single shaft shredder has been successfully used in multiple waste treatment and recycling projects. It is a powerful tool for efficient waste processing, improves resource utilization, and has made important contributions to environmental protection. It is receiving widespread attention and recognition.

Address :

Wanshan Rd., Xingyang, Zhengzhou,CHINAWhatsApp :

+86 132 1319 7820 (7x24h online)Phone :

+86(371)64693430E-Mail :

info@tonglishredder.com