WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

Metal shredder equipment belongs to the main equipment in the processing of scrap metal production line, with a complete range of models and varieties. The properties of metal scrap determine the model of the equipment. Different metal scraps have different materials, properties, components, and different hardness. Only by choosing the appropriate model can you get the most benefit. Common wastes, such as metal cans, small paint buckets, tires, dry powder fire extinguishers, etc., are relatively easy to break. Choosing small-sized equipment will not only have high shredding efficiency, but also will not waste investment costs. Small metal can shredders are favored by customers because of low cost and high profit.

In recent years, waste such as used cans has been increasing on the basis of billions, which has caused great pressure on environmental resources. With the arrival of summer and the popularity of various party night market stalls, the number of waste cans has increased several times. The can shredder can shred the cans centrally, separate and recycle aluminum and iron, and quickly purify the social environment. The can shredder has novel structure, high quality, strong durability, good stability, reliable operation, and a multi-purpose machine, which can adapt to various small waste materials.

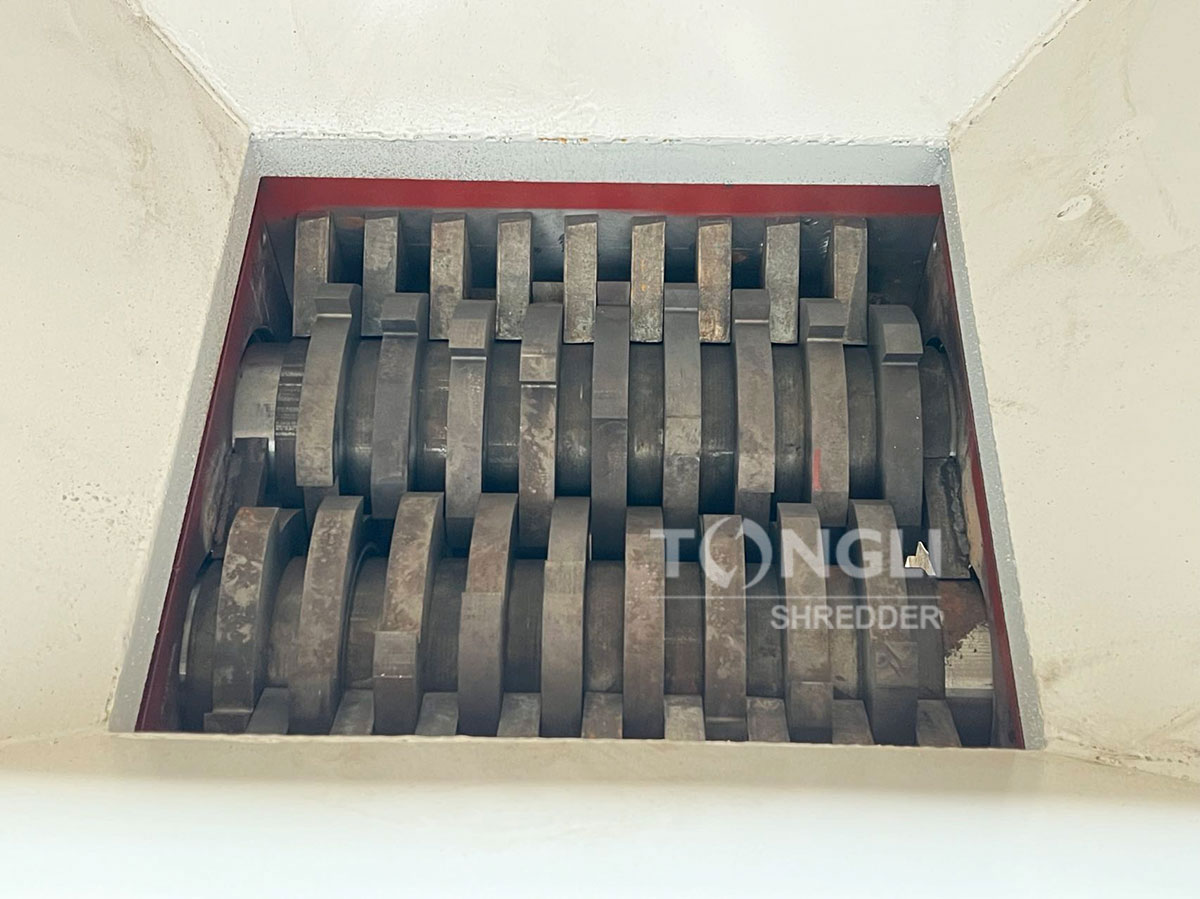

Small metal can shredder, also known as shearing shredder, can reduce the size of the material by cutting, tearing and squeezing, and the thickness of the knife and the number of claws can be replaced according to different materials. When shredding hollow materials, it can be equipped with a pressing device to increase the output. A rotary screen can also be added to control the size of the discharge. Low speed operation, noise and dust can reach industry standards. Scrap metal shredders are generally double shafts, because the double shafts have more powerful power and higher efficiency during the shredding process, and the knives of the double shaft shredders are not flush, but spiral, shredding After the material is more uniform. The double shaft shredder provides reliable quality equipment for the crushing and volume reduction treatment in the early stage of waste recycling.

Features of small metal can shredder equipment:

1. The main body is welded with high-quality steel plates to eliminate application processing, and the whole machine is machined to ensure the stability of the equipment under heavy loads for a long time;

2. The bearing/sealed bearing seat adopts the patented splicing and disassembling type, which can quickly remove the moving knife, fixed knife, bearing and other components, easy to maintain and replace the tool, and the unique sealing structure can effectively block the contact of broken objects and grease, and deal with liquid The material can also protect bearings and gears, etc.;

3. The moving knife material is made of special alloy tools, steel forging blanks, precision machining, multiple heat treatment and low temperature freezing heat treatment technology, the overall toughness and hardness are consistent, and can be reused to ensure cutting performance and service time. The fixed knife adopts the patented hook type installation, which optimizes the tool replacement function and makes the tool maintenance and replacement better;

4. The cutter shaft is made of high-strength and heavy-duty special steel, which more reasonably cooperates with the cutter to provide powerful power for cutting.

Problems that need to be paid attention to in the operation of the small metal can shredder:

1. Always check the connecting bolts, especially the square head bolts that fix the toothed tooth plate, to prevent loosening;

2. Lubricate each bearing, pinion and special-shaped gear 1-2 times per shift to ensure sufficient lubricating oil inside the bearing and reduce excessive disassembly and damage of sleeves and gears;

3. The feeding particle size should not exceed the specified size, and the feeding should be connected evenly to prevent material blocking;

4. Always check the temperature of the spare bearing, the temperature rise of the bearing bush should not exceed the room temperature 25-30 ℃;

5. The bearing slideway of the moving roller should be cleaned frequently to remove dust and miscellaneous materials, so as to prevent the material from entering the moving roller and cannot move and cause accidents;

6. In the event of a sudden power failure, the power supply of the motor must be disconnected first to prevent accidents caused by sudden power calls. Then take out the unshredded material in the shredder to prevent the shredder from cutting off the safety pin due to excessive load when it is started;

7. Pay attention to observe the working condition of the safety pin at any time, and immediately cut off the power supply after the safety pin is cut off to prevent the large pulley from idling on the sleeve for too long, which will cause excessive wear on its mating surface, and even cause shaft holding and other accidents. ;

8. The operator must strictly implement the safety technical operation rules to prevent the phenomenon of random operation and prevent the occurrence of personal and equipment accidents.

The price of small metal can shredder equipment ranges from tens of thousands to hundreds of thousands, and the output is also divided into large and small. For detailed configuration, pictures, videos and prices, please consult us for more details.

Address :

Wanshan Rd., Xingyang, Zhengzhou,CHINAWhatsApp :

+86 132 1319 7820 (7x24h online)Phone :

+86(371)64693430E-Mail :

info@tonglishredder.com