WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

Scrap metal is a renewable resource, and metal shredder is a kind of equipment for scrap metal processing, mainly used to process scrap metal. After years of perfect production, the metal shredder series products are very popular in the market. The following is a detailed introduction to the principles and details of the metal shredder that is popular in the market.

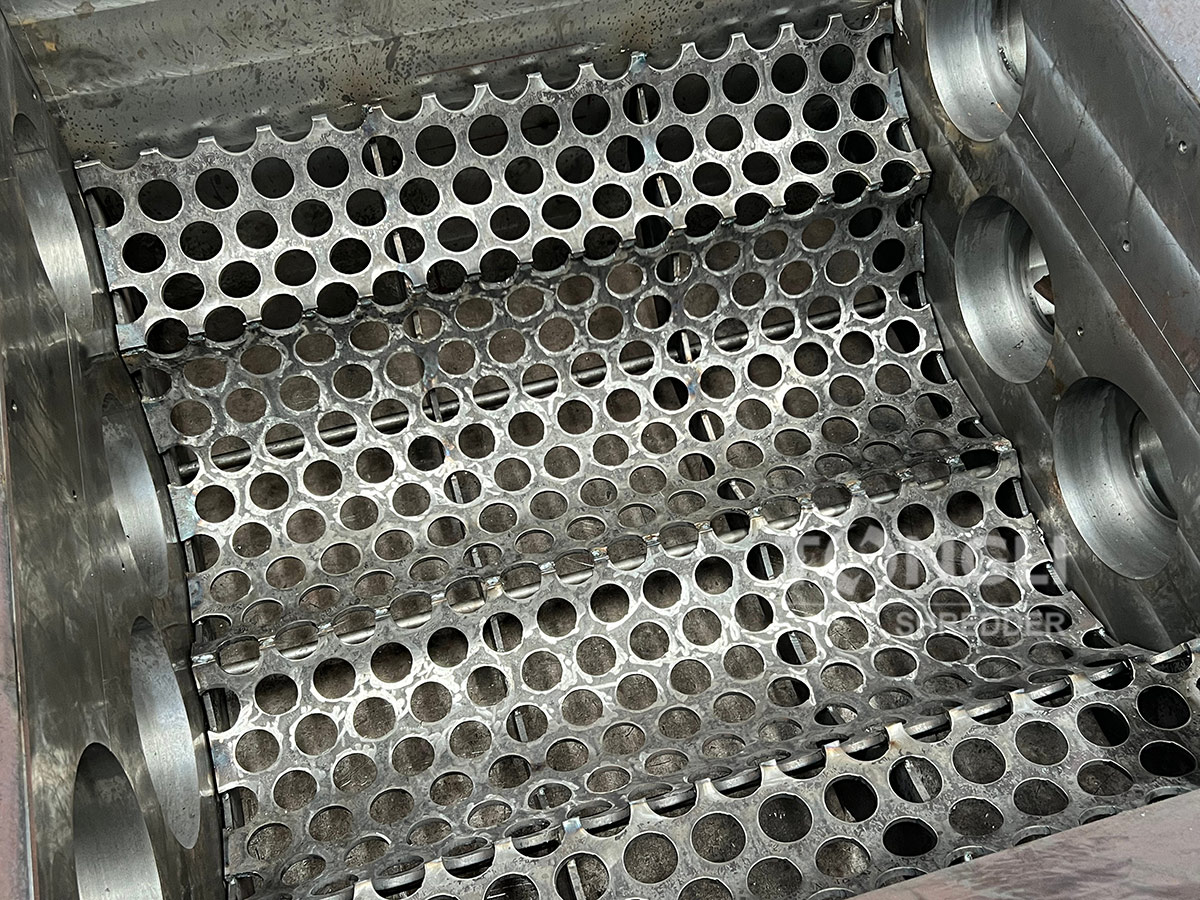

The production principle of the metal shredder equipment is that the material enters the shredder chamber through the feeding system, the shredding blade is installed on the bearing, and the material is torn into small pieces by the shredding blade and discharged from the lower part. The material processed by the metal shredder equipment can greatly reduce the volume occupied by the material. Its main working steps are to reduce the size of scrap metal through production methods such as cutting, tearing and extrusion, and the gear motor is driven to save time. It can also be operated by a single person to save energy and achieve the purpose of convenient transportation. After passing through the shredder The processed materials can directly reach secondary recycling. After coarse crushing, some waste metal materials can be further finely crushed using the configured metal crusher equipment.

Metal shredder equipment is usually designed according to the characteristics of scrap metal materials. The internal structure can be adjusted for special materials, and it can exert unique advantages in efficiency when used. In terms of purchasing metal shredders, due to the wide range of uses of shredders, there are metal shredders, plastic shredders, rubber shredders, etc., all of which are the same in appearance, but have different uses. The knives are also different, and the equipped spindle and reducer are also different, so don't try to buy unqualified metal shredders cheaply.

The production quality of metal shredder equipment is high. Its important parts are quenched at high temperature, and the blade is sharp and not easy to wear. Machinable waste metal products include scrapped car casings, old steel bars, paint buckets, scrap steel, cans, metal bottles, paint buckets, scrap thin iron sheets, scrap iron scraps, etc. These scrap metals can save resources and save Cost, increase the stability of scrap metal and protect the environment. The equipment can be customized according to some special market demands, providing reliable equipment for volume reduction treatment of scrap metal.

The metal shredder is convenient to produce and saves labor costs, and has become an indispensable equipment in metal recycling. When customers purchase, they must understand the principle of the metal shredder in detail and check its details carefully. As the saying goes, "details determine success or failure." The professionalism of regular manufacturers is reflected in every detail.

Address :

Wanshan Rd., Xingyang, Zhengzhou,CHINAWhatsApp :

+86 132 1319 7820 (7x24h online)Phone :

+86(371)64693430E-Mail :

info@tonglishredder.com