WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

This series use Micro-computer(PC) automatic control. Equipped with start, stop, reversion and overload automatic reverse function. Also having low speed, high torque, low noise and other features. Easy to replace blade by using split bearing.Suitable for very big, thick and hard materials, such as: TV, washing machine, refrigerator shell, large scale pipe, pipe fitting,forklift pallet, tire, drum, car shell, copper, aluminum and iron with thickness less than 10mm.

APPLICATION

Scrap metal recycling processing, domestic/industrial/medical/Construction waste, waste tire recycling, waste plastic processing, waste wood processing,scrapped car dismantling, waste metal recycling etc.

TECHNICAL PARAMETERS

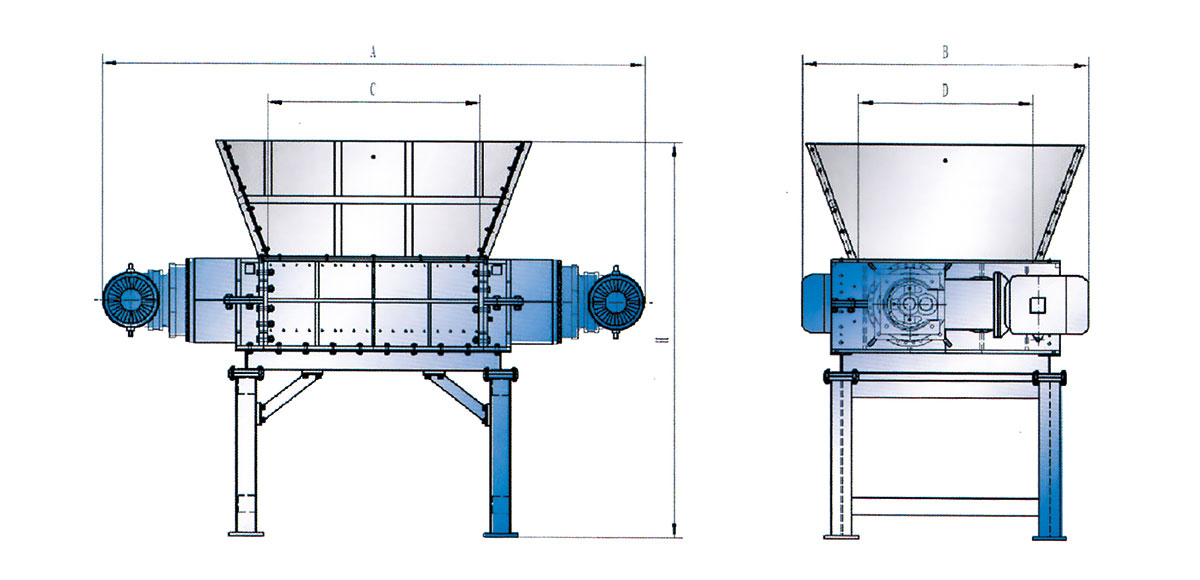

| Model | TL61180 | TL61180A | TL61210 | TL61250 |

| A(mm) | 4620 | 4620 | 2730 | 5200 |

| B(mm) | 1080 | 1080 | 4670 | 3400 |

| C(mm) | 2440 | 2440 | 2470 | 2570 |

| D(mm) | 1800 | 1800 | 2100 | 1600 |

| H(mm) | 1500 | 1500 | 1500 | 3400 |

| Blade turning diameter | Φ800 | Φ756 | Φ800 | Φ800 |

| Main shaft speed(r/min) | 7.5 | 5.4&3.6 | 7.5 | 7.5 |

| Rotor blade quantity(pcs) | 24 | 24 | 28 | 33 |

| Blade thickness | 75 | 75 | 75 | 75 |

| Machine power | 55+55 | 55+55 | 75+75 | 75+75 |

NOTE

1.The standard thickness of rotor blade is 75mm, also available in 50mm and 100mm,user can choose blade based on final output size after crushing.

2.Rotor blade is single claw blade, if need double claw or multiple claw, please contact with our sales department.

3.GL61180A is the improvement based on GL61180, changing reducer base to bigger size, reduce rotating speed and increase torque.

Address :

Wanshan Rd., Xingyang, Zhengzhou,CHINAWhatsApp :

+86 132 1319 7820 (7x24h online)Phone :

+86(371)64693430E-Mail :

info@tonglishredder.com