WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

WhatsApp: +86 132 1319 7820 (7x24h online) info@tonglishredder.comManufacturer of scrap metal recycling plant

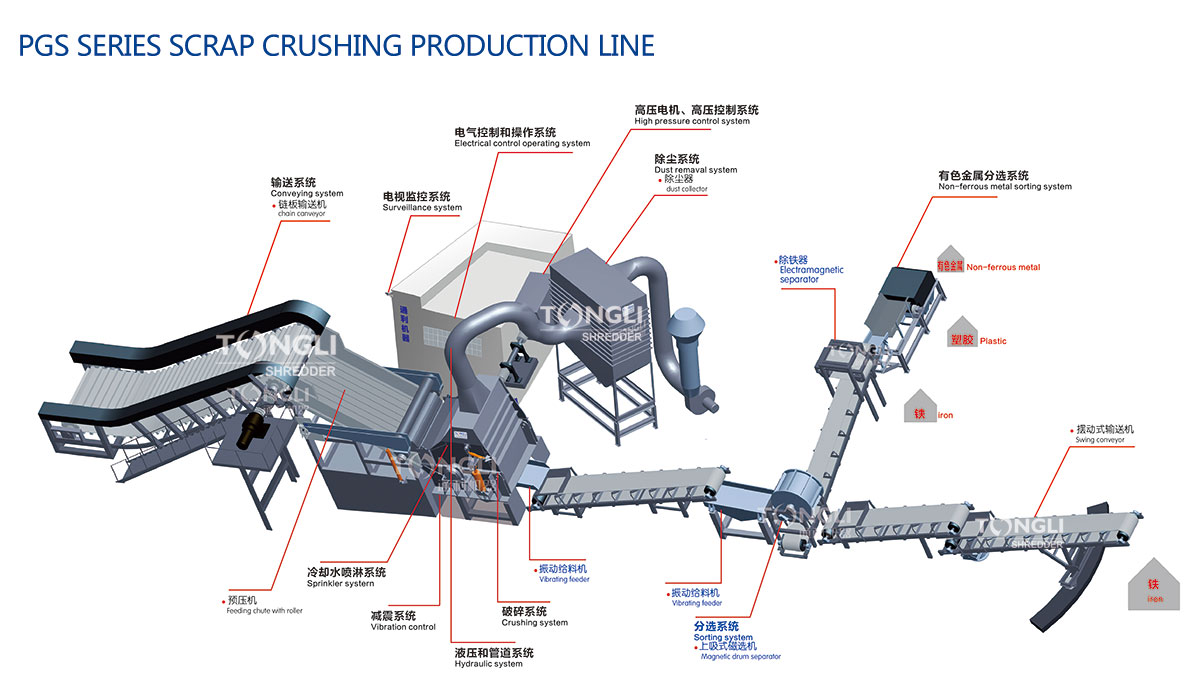

TONGLI PGX Scrap metal recycling plant is the ideal solution for a wide range of ferrous and non ferrous metal applications in scrap yards and steel works. It is equipped with Hammermill, a powful motor, fully automatic electric control, hydraulic drive, sorting line, monitoring system,etc.

TONGLI PGX series scrap metal shredding line, shred large scrap metals to get 99.5% pure steel/iron with higher efficiency and big productivity.

APPLICATION

We are dedicated to provide reliable and effective solutions to our customers who are in persuit of scrap metal recycling industry. Our PGS series scrap metal recycling plant is good to shred scrap materials as following:

Size of Final products after shredding depends on the hole size of sieve plate, 140-200mm is the popular output size of large scrap metal recycling plant for steel mills, we can customize the hole size of sieve plate as our customer's needs. Final Products are around 1.2tons/m3, recyclable rate is more than 90%, and get 99.5% pure steel/iron. With high recycling efficiency, TONGLI large scrap metal recycling plant can be applied widely in scrap yards and steel works.

TECHNICAL PARAMETERS

| Model | Feed width(mm) | Host power(kw) | Average yield(t/h) |

| PGX-400 | 1400 | 400Kw/535hp | 8-12 |

| PGX-500 | 1600 | 500Kw/670hp | 10-15 |

| PGX-600 | 1600 | 600Kw/800hp | 15-20 |

| PGX-750 | 2200 | 750Kw/1000hp | 20-25 |

| PGX-900 | 2200 | 900Kw/1200hp | 20-30 |

| PGX-1200 | 2200 | 1200Kw/1600hp | 30-35 |

| PGX-1500 | 2500 | 1500Kw/2000hp | 35-45 |

| PGX-2250 | 2500 | 2250Kw/3000hp | 50-60 |

| PGX-3000 | 2600 | 3000Kw/4000hp | 50-70 |

| PGX-4500 | 2700 | 4500Kw/6000hp | 80-160 |

CONFIGURATION

Our PGX series scrap metal recycling plant includes the entire line of equipment :

1. Pre-shredder with twin-shaft shredders (Optional configuration, mainly shred large scraps into small scraps for increasing production capacity);

2. Hammermill shredder with pre-press machine (Shred scraps into small size 140-160mm granularity);

3. Vibrating feeder (Make discharging products evenly for better sorting);

4. Magnetic separator (For sorting ferrous and non-ferrous metal);

5. Chain conveyor & Belt conveyor (For feeding and discharging);

6. Dust collector (Prevent pollution); High pressure control system & Electric control system (Fully automatic);

7. Monitoring system (Better checking the entire line run well);

8. Sprinkler System (Reduce dust pollution) Hydraulic system

Address :

Wanshan Rd., Xingyang, Zhengzhou,CHINAWhatsApp :

+86 132 1319 7820 (7x24h online)Phone :

+86(371)64693430E-Mail :

info@tonglishredder.com